Project description

When it comes to redevelopment projects, they don’t come much more complex than No1 Grosvenor Square with its rebuilt facade, SFS (steel framed structure) on springs and its listed building status.

No 1 Grosvenor Square is a building of significant historical importance located in the heart of Mayfair and formerly home to the US Embassy and the Canadian High Commission. Its precise replica of the Oval Office, created by Ambassador Joseph P Kennedy in 1938, is said to have inspired his children to want to achieve the dizzying heights of US President.

Located in the heart of the Duke of Westminster’s Grosvenor Estate the building was bought by Lodha in 2013 and has been subject to extensive renovation works ever since resulting in the impressive development of high end luxury apartments complete with acoustic windows it is today.

Tom Wright, Managing Director at George Barnsdale was involved from the earliest stages of the project to oversee the design, testing, manufacture and installation of some of the very highest performing historic windows in London. Here he describes some of the challenges the project presented to the Barnsdale team and how they overcame them…

How did it all begin?

“We initially worked with Rupert Willard from Eric Parry Architects prior to the main contractor, Mace’s appointment in 2016. Following the work we did on the 20 Grosvenor Square project which was a similar historic renovation with a retained facade, the client recognised our experience and knowledge of the requirements of the Grosvenor estate. It was clear from the beginning that the client really wanted to respect the history of the building, retaining the beautiful Georgian aesthetic but also wanted us to find a way to give clients the warmest, quietest and most secure timber windows possible.”

“Fortunately, given the complexity of this project the architect and client had the foresight to involve us at the earliest opportunity. We provided a detailed programme through the tender stage to ensure that the contractor understood the critical timeframes and could make decisions at the right time. As time went on, such collaboration with architects, facade consultants, acoustic engineers, conservation specialists and quantity surveyors etc proved invaluable to the process of overcoming issues as soon as they arose and helped with the smooth running of the project.”

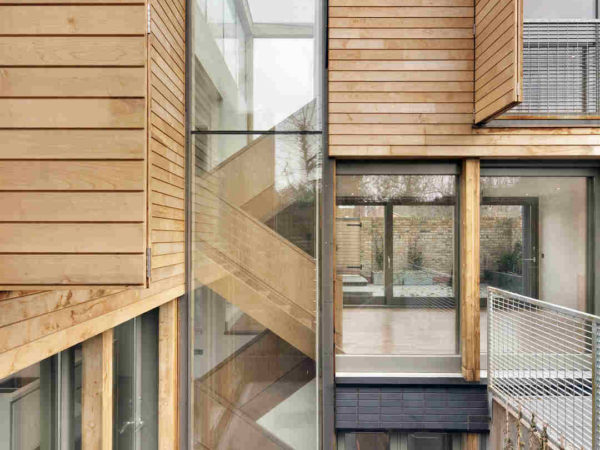

Due to the nature of the project where an apartment has recently sold for £140million, residents could not be expected to put up with unwanted noise. One of the sources was the nearby underground trains that rumble and resonate through the old buildings in the area. The solution was a very complex internal rebuild involving the entire interior of the building being reconstructed on springs. Tom continues: “Whilst the SFS was designed to move, the external walls of the building remained static so the technical challenge of installing windows in this scenario where there was marked differential movement was considerable. We worked closely with Illbruck, to develop an interface that would work with their SFS facade detail taking into account waterproofing, acoustic and weather performance.”

Hayden Darley, Technical Director explains further “The external face of the building is not flat it features brick and stone work that steps in and out, the sequence of works meant that windows were installed into the build long before the external face was built meaning items were effectively located in mid-air and positioned in the correct place with the use of gridlines e.g. W1 is positioned 300mm in front of gridline A, but W2 might have only been 150mm from gridline A. this meant that we had nearly 70 interface drawings showing how all the windows were to be installed.”

In line with many projects, George Barsndale was provided with a detailed glazing analysis that considered the location, elevation, window type, window covering (curtain/blinds, including colour, distance and material) and heating method. This defined the requirement for heat strengthening and allowed it to be specified only where required which helped manage the budget. The heat strengthened glazing specification was highly specialist.

Acoustic challenge

Going back to the acoustic challenge, the windows were specified to meet the octave specific noise reduction and the whole window was validated with test data not just the glazing data. The latter is not a reliable method of determining acoustic performance. Tom continues “Using a vast array of technical and acoustic data collected over many years of testing, we were able to specify the optimal solution. We always advise clients to request whole window data because as soon as glazing is put into a frame, the performance is affected. We take into account the entire design of the window and the installation detail to ensure the highest performance.”

Security is another important consideration in high end developments such as One Grosvenor Square and George Barnsdale integrated security contacts into the design and fitted custom handles to the doors.

Commenting on the main challenges of the project, Hayden Darley, Technical Director said: “The weight of the windows was a bit of an issue since the glass was so heavy, there was also quite a lot of effort put into the supply chain for the glazing and the overall difficulties of installing the windows before the external envelope was completed.”